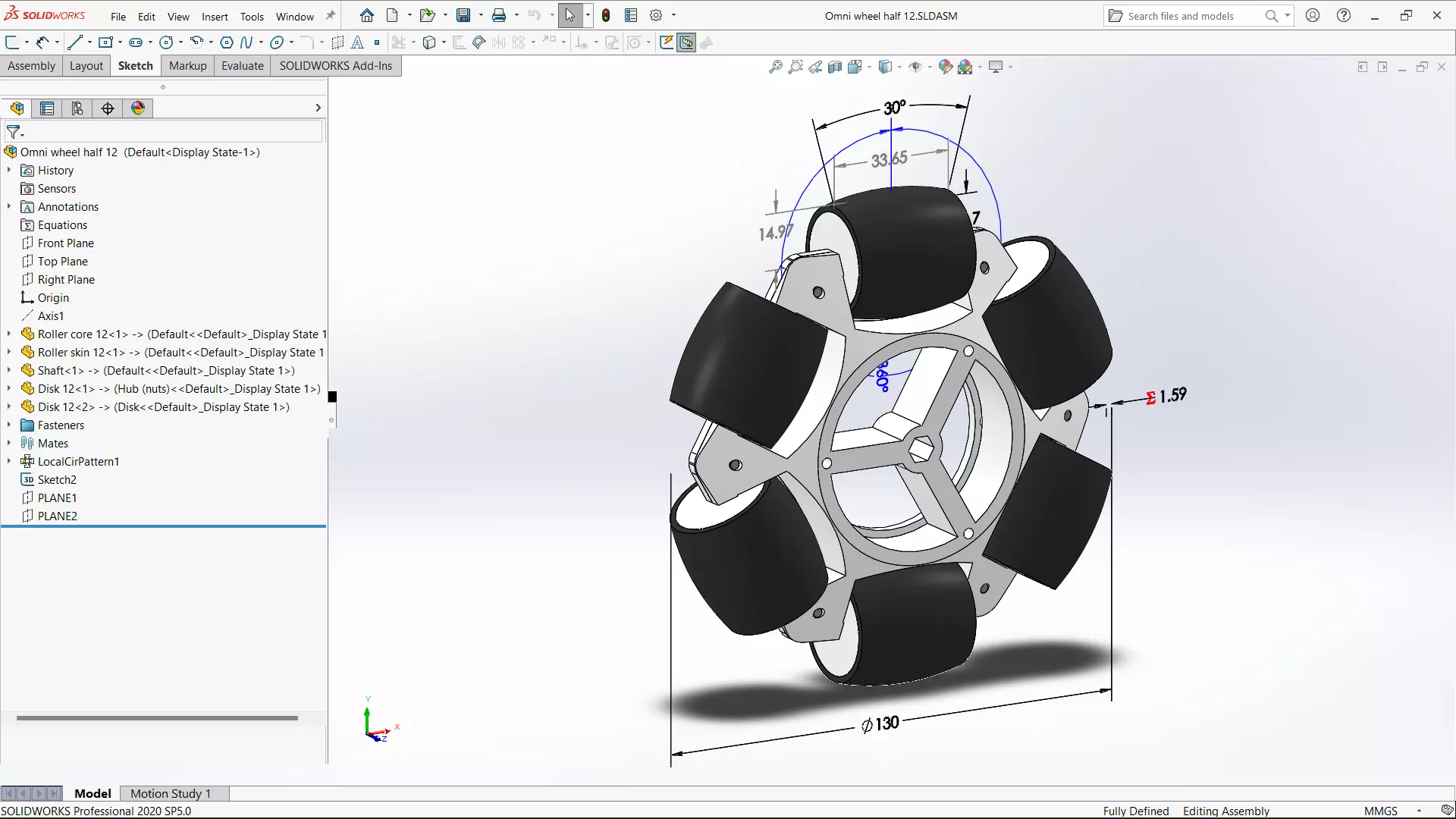

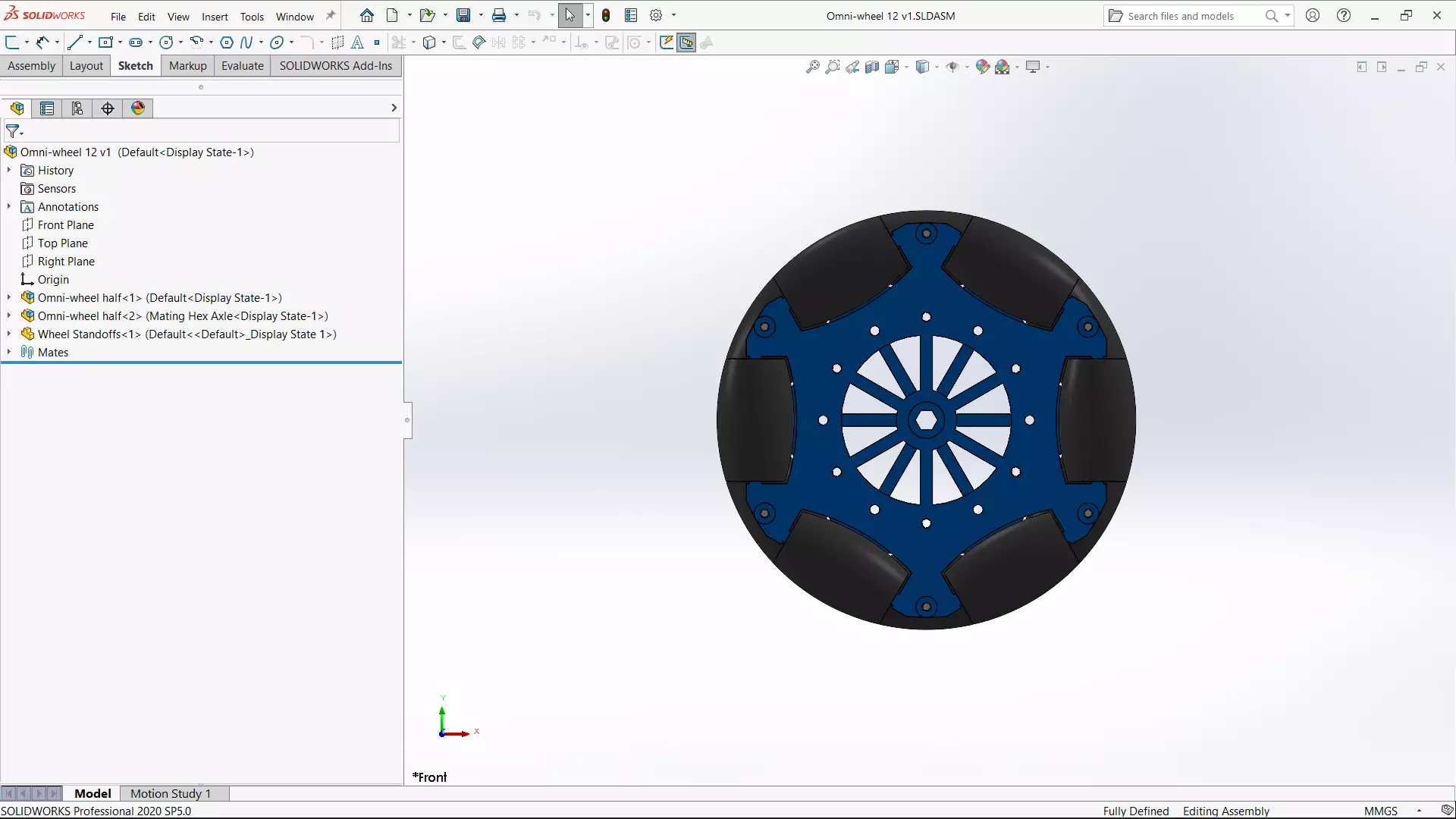

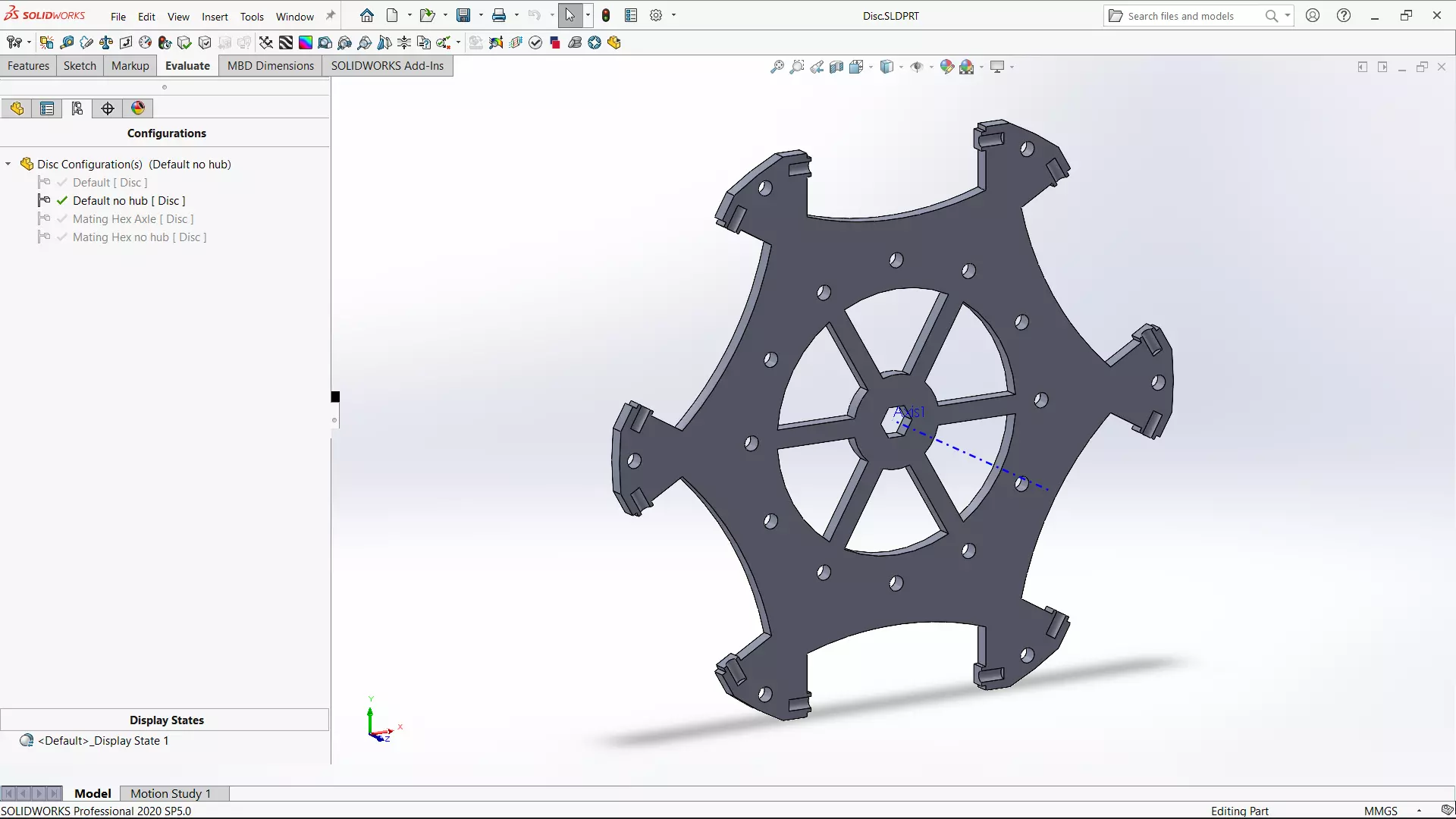

3D-printable omni-wheel

This is a 12-roller robot 3D-printed DIY omni-wheel - a part of Kiddo companion robot. This open-source design incudes 3MF, STL, STEP and SolidWorks files.

Included are 3 verions - as the omni-wheel design evolved:

- Rollers coated in urethane rubber, 130mm OD - recommended

- v2 - rollers in a 3D-printed TPU soft jacket, 130mm OD

- v1 - rollers in a 3D-printed TPU soft jacket

All three omni-wheel version were 3D-printed on a Prusa MK3S.

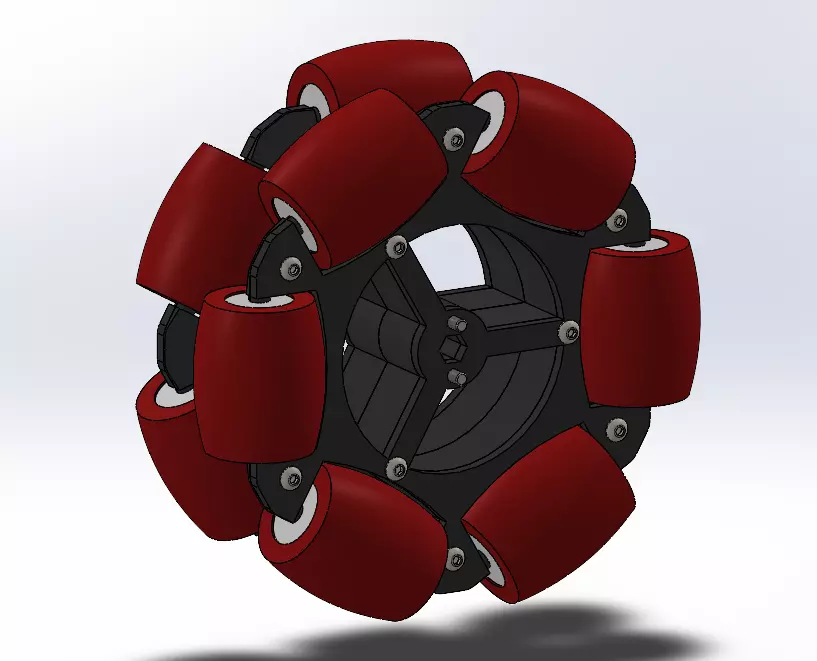

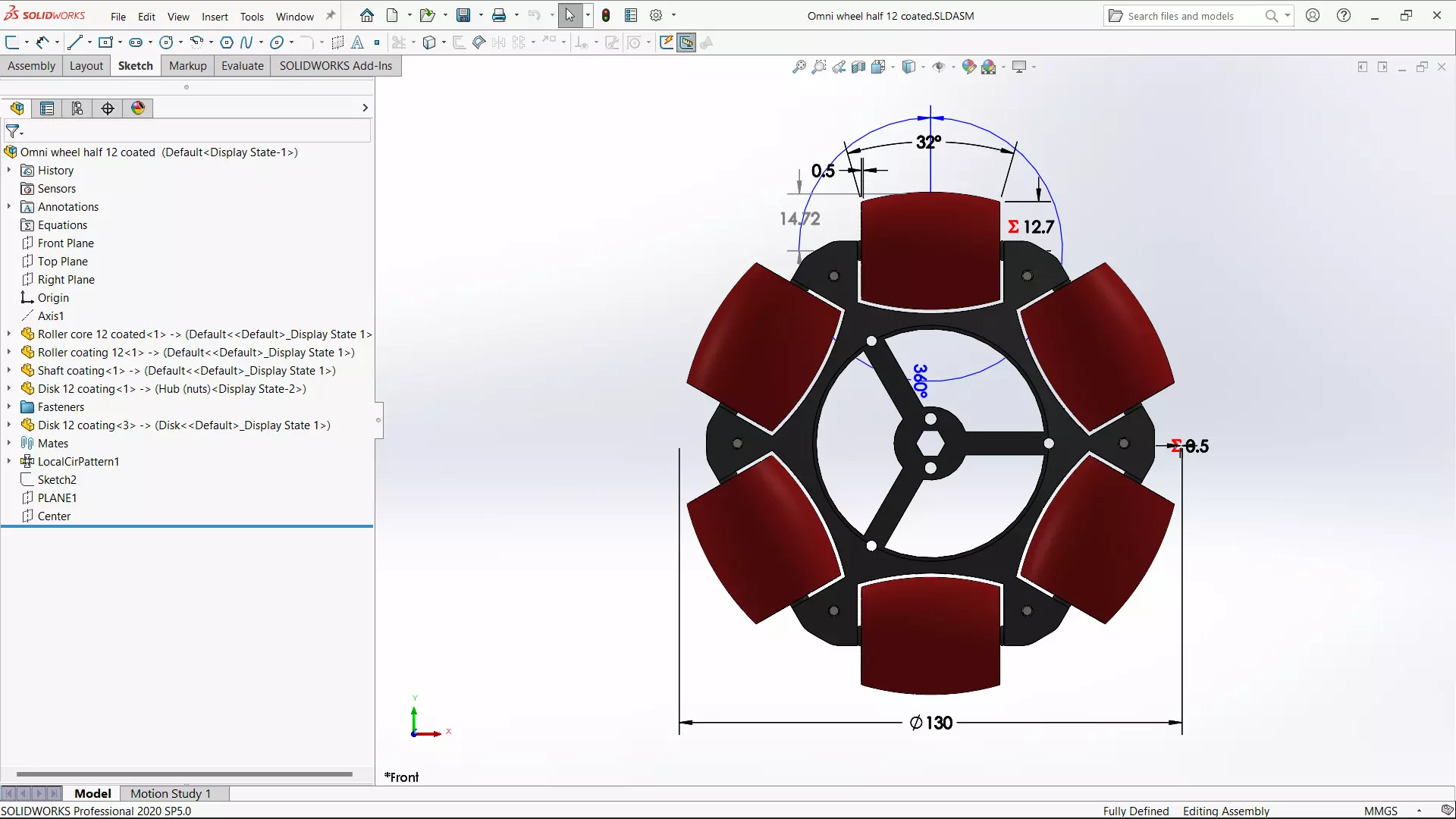

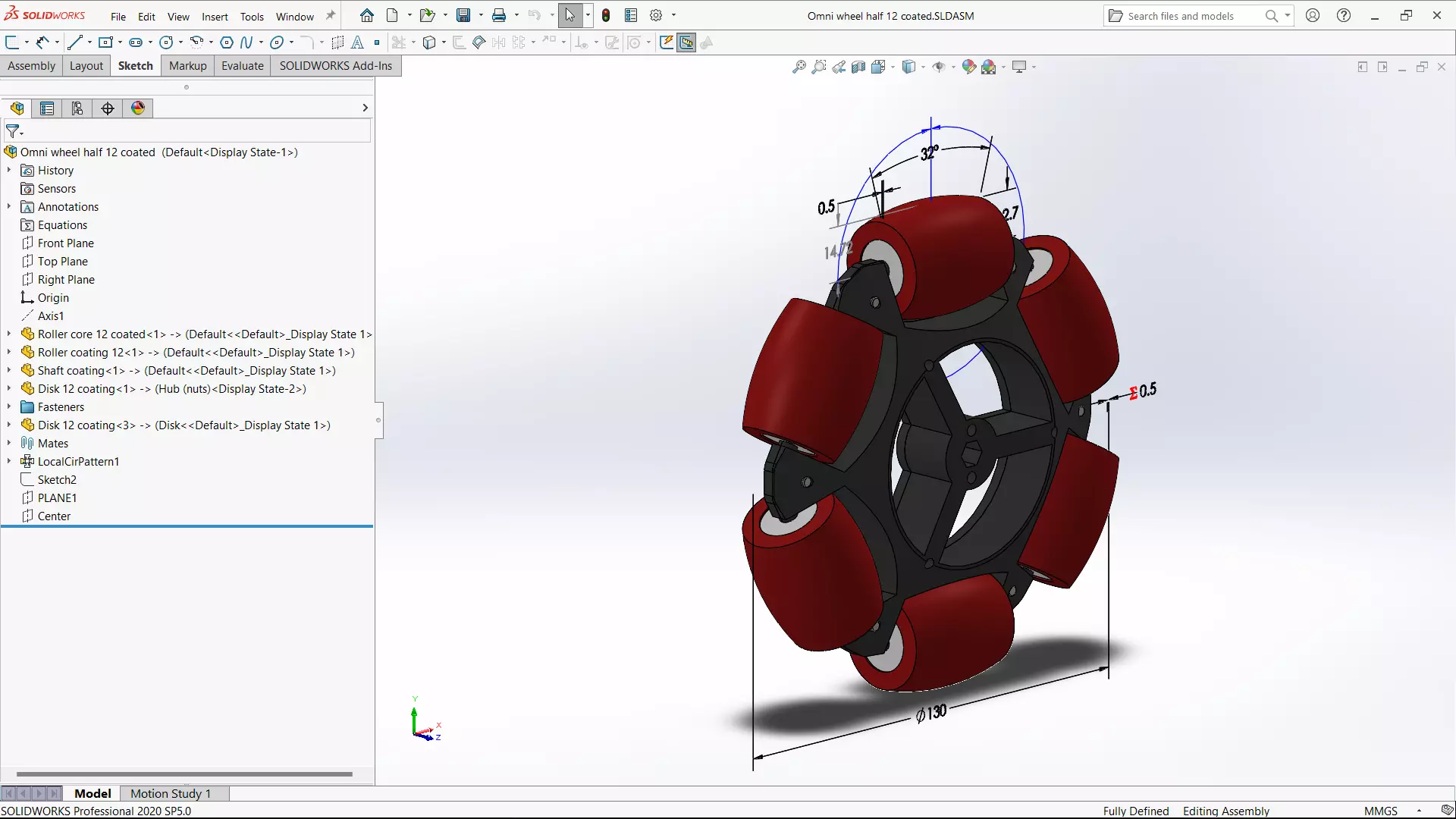

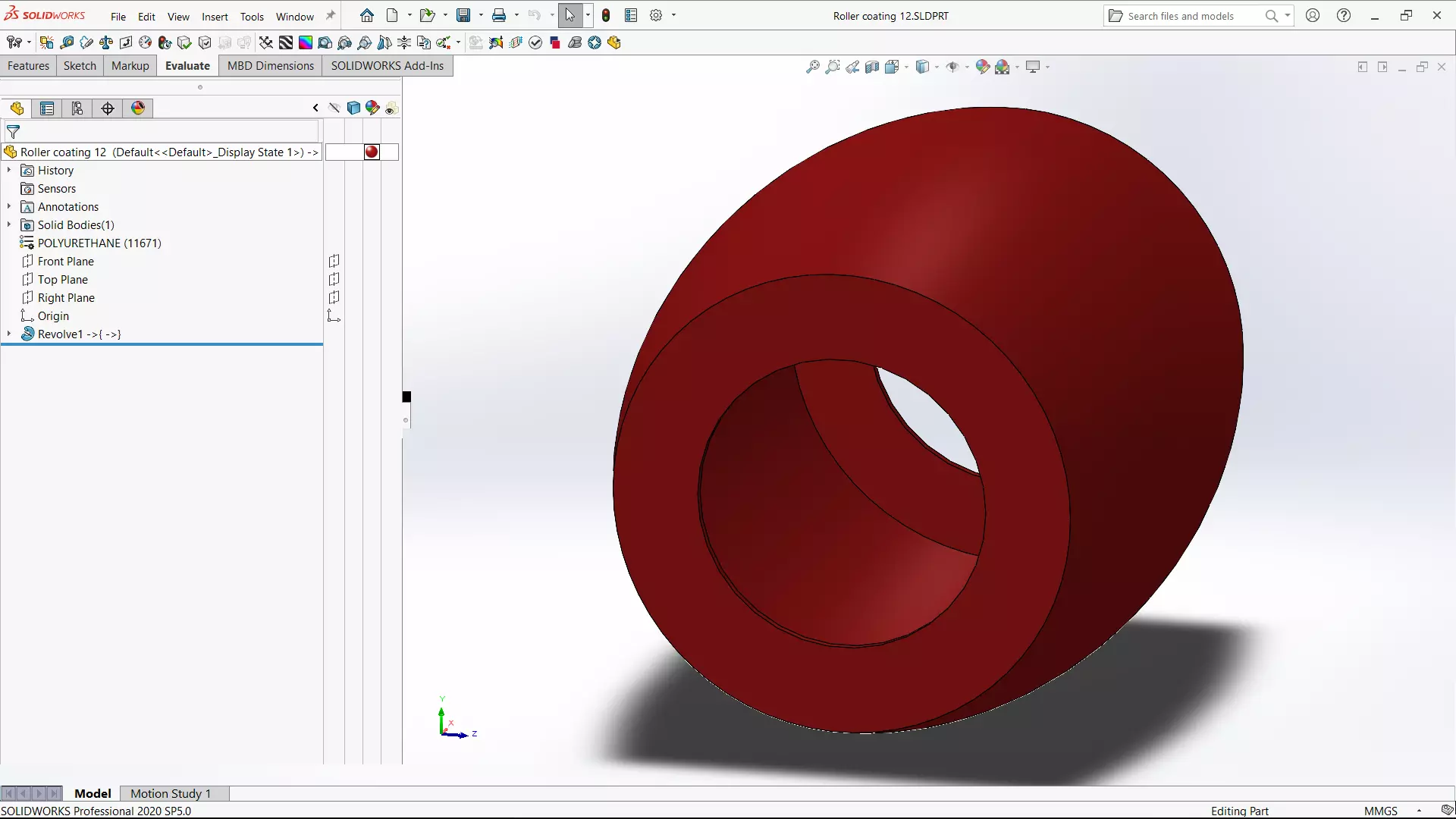

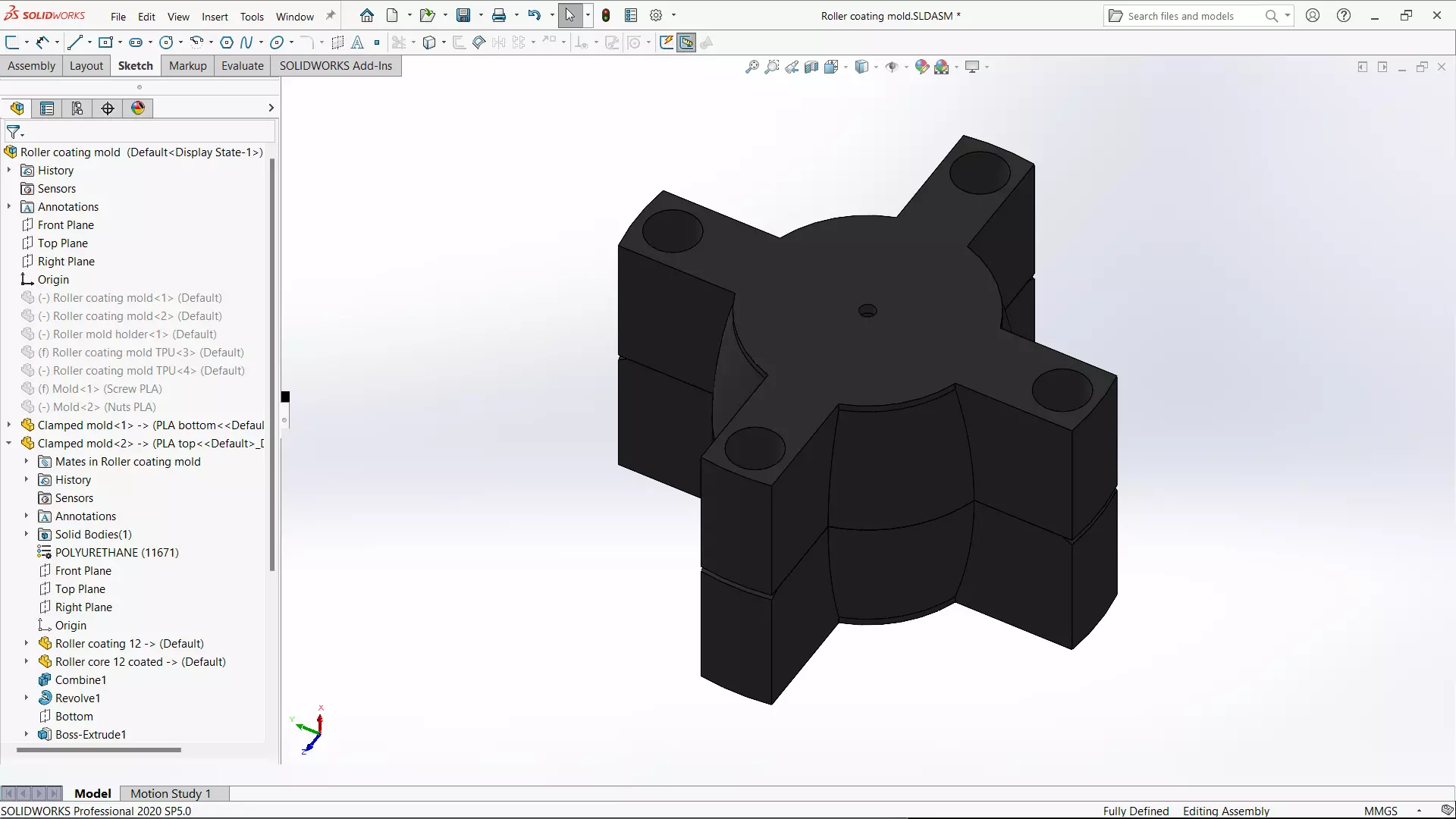

An omni-wheel coated in silicon rubber

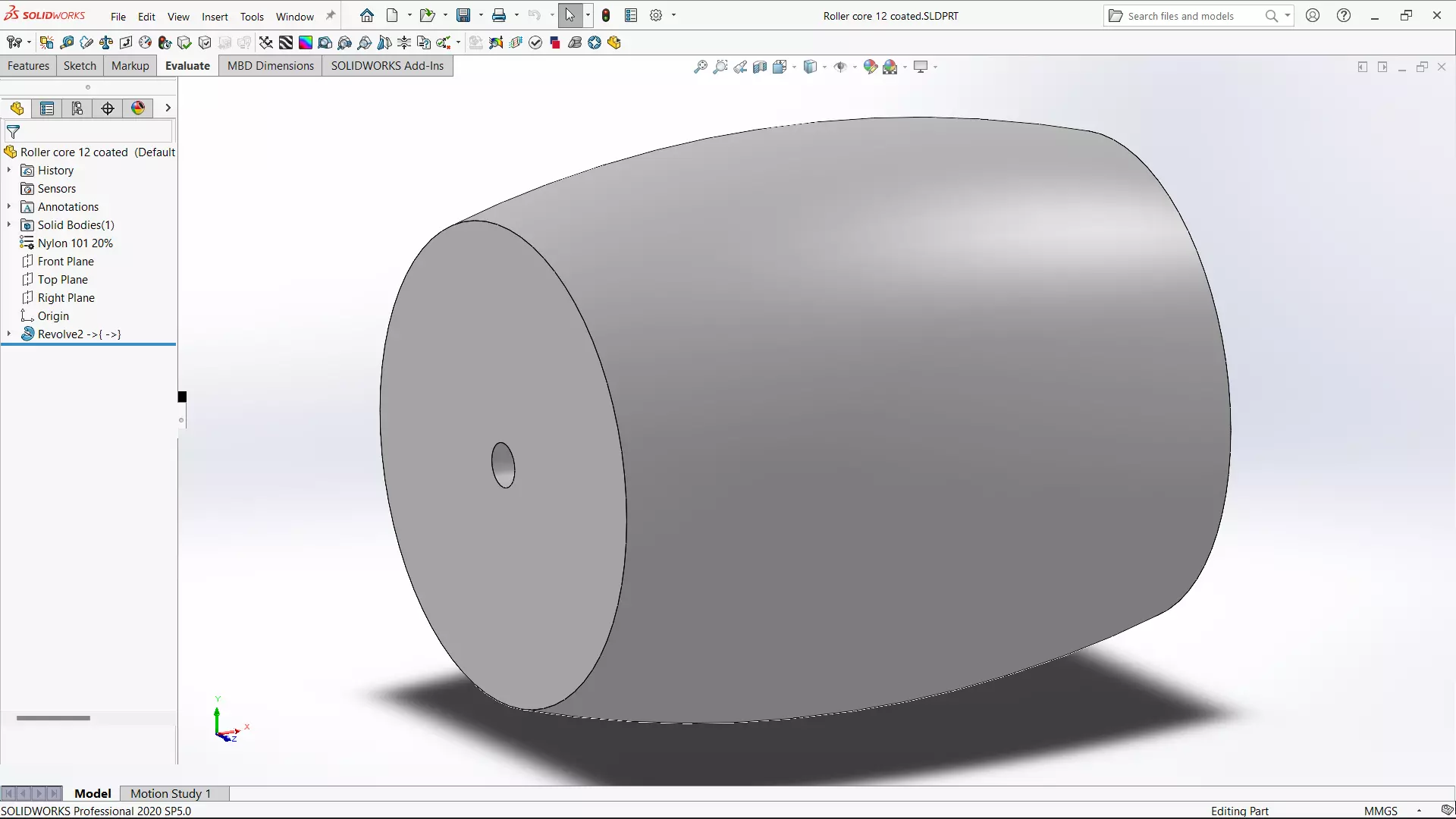

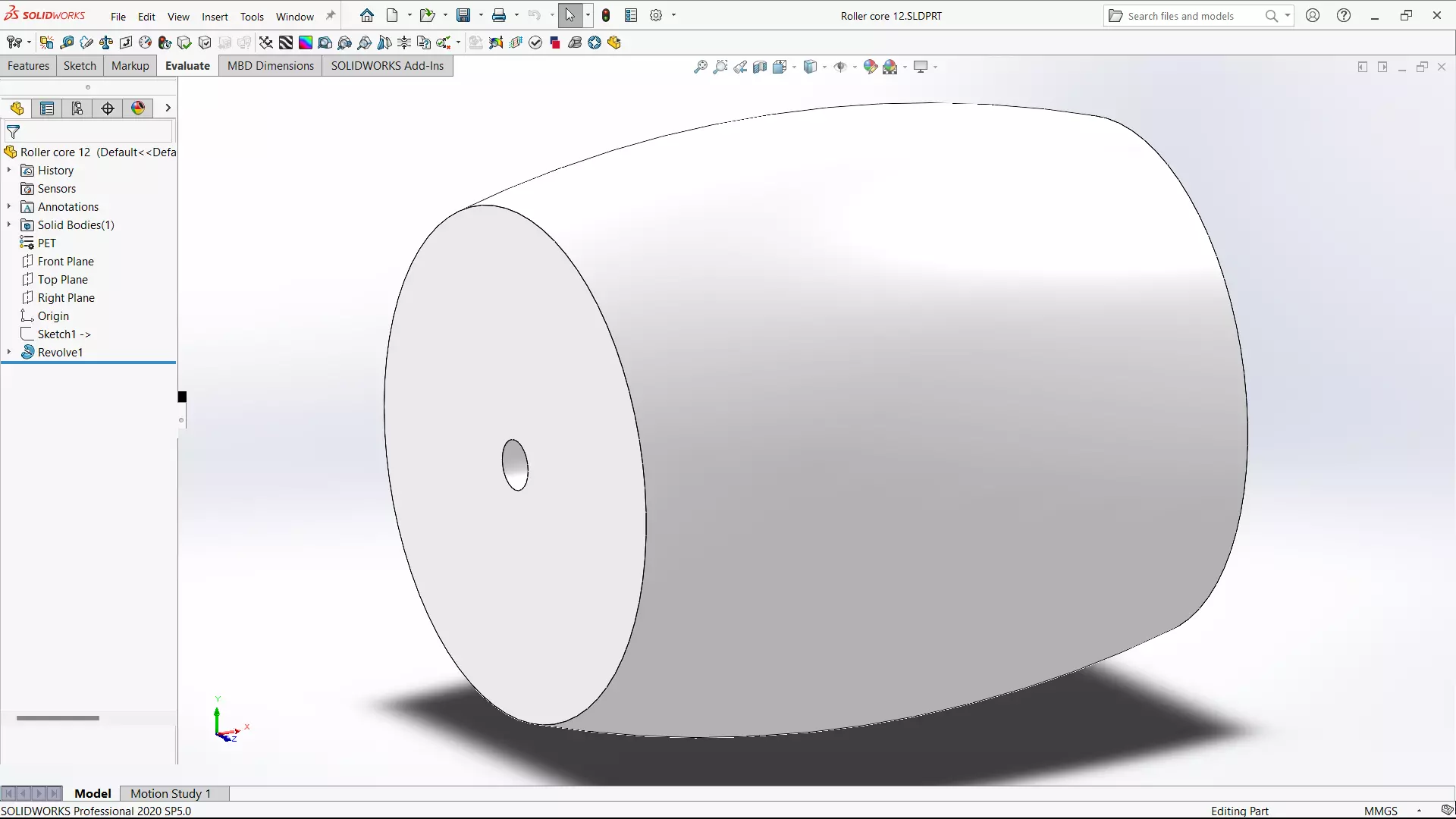

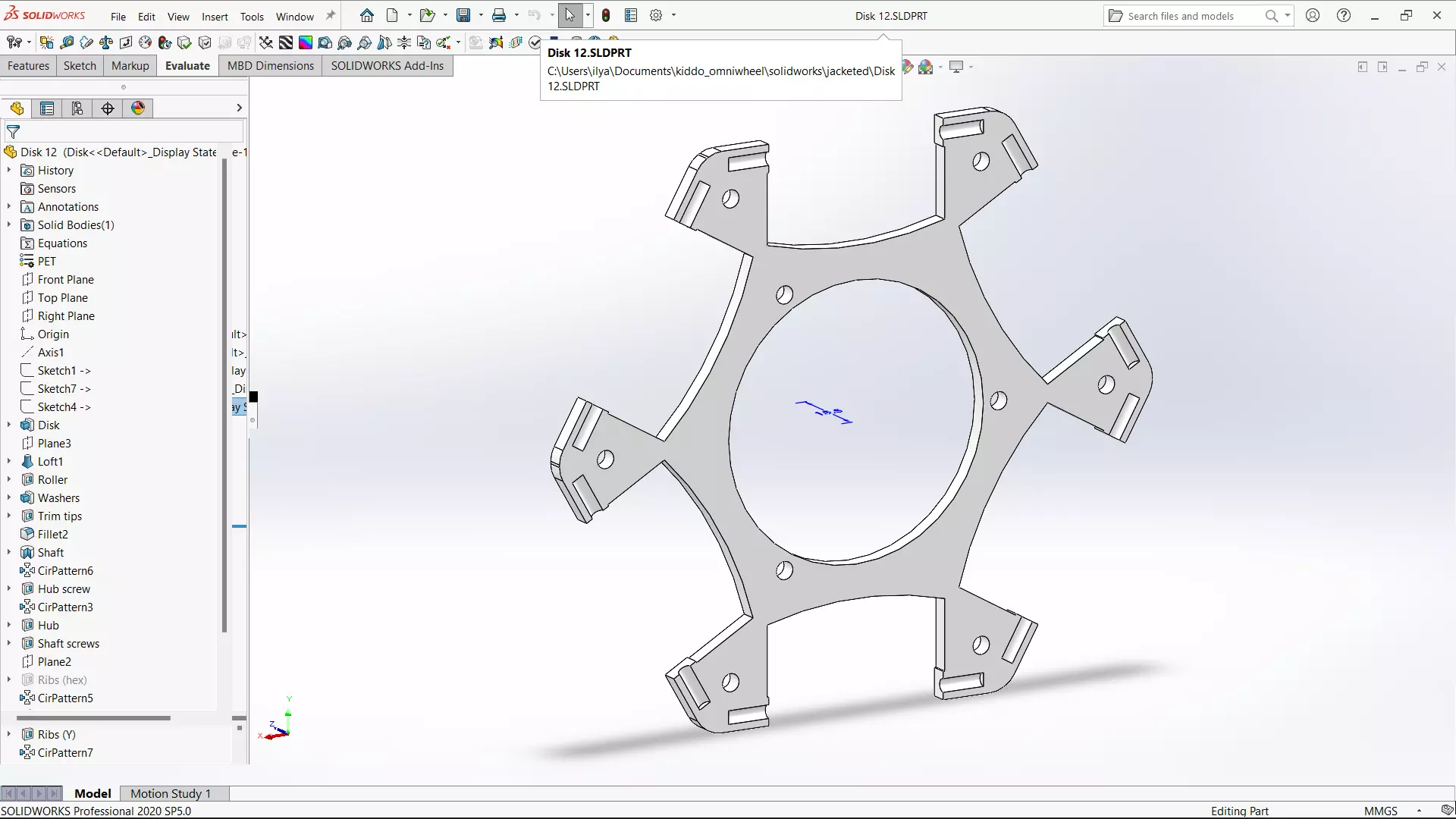

- 12-rollers

- 130mm OD

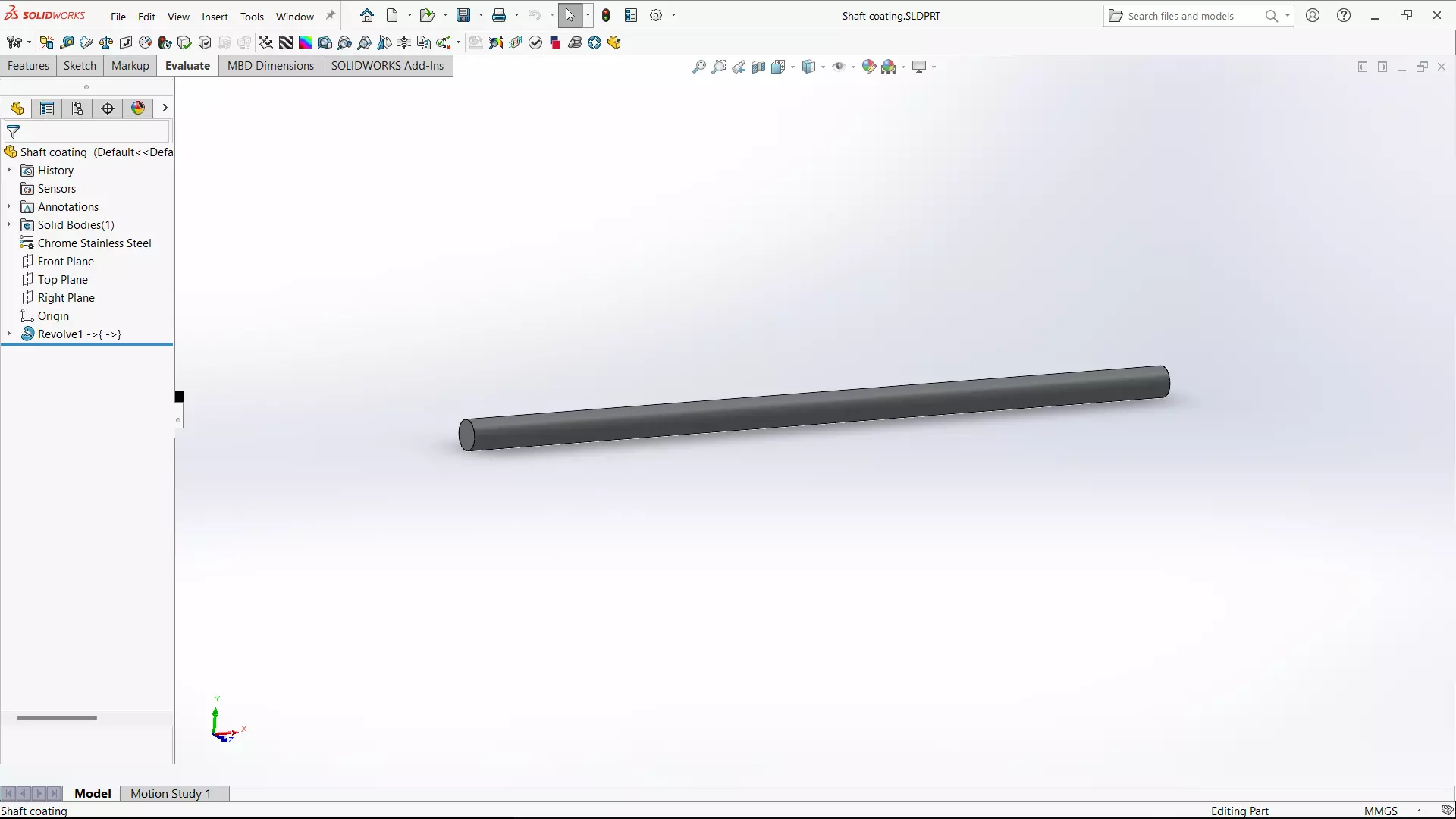

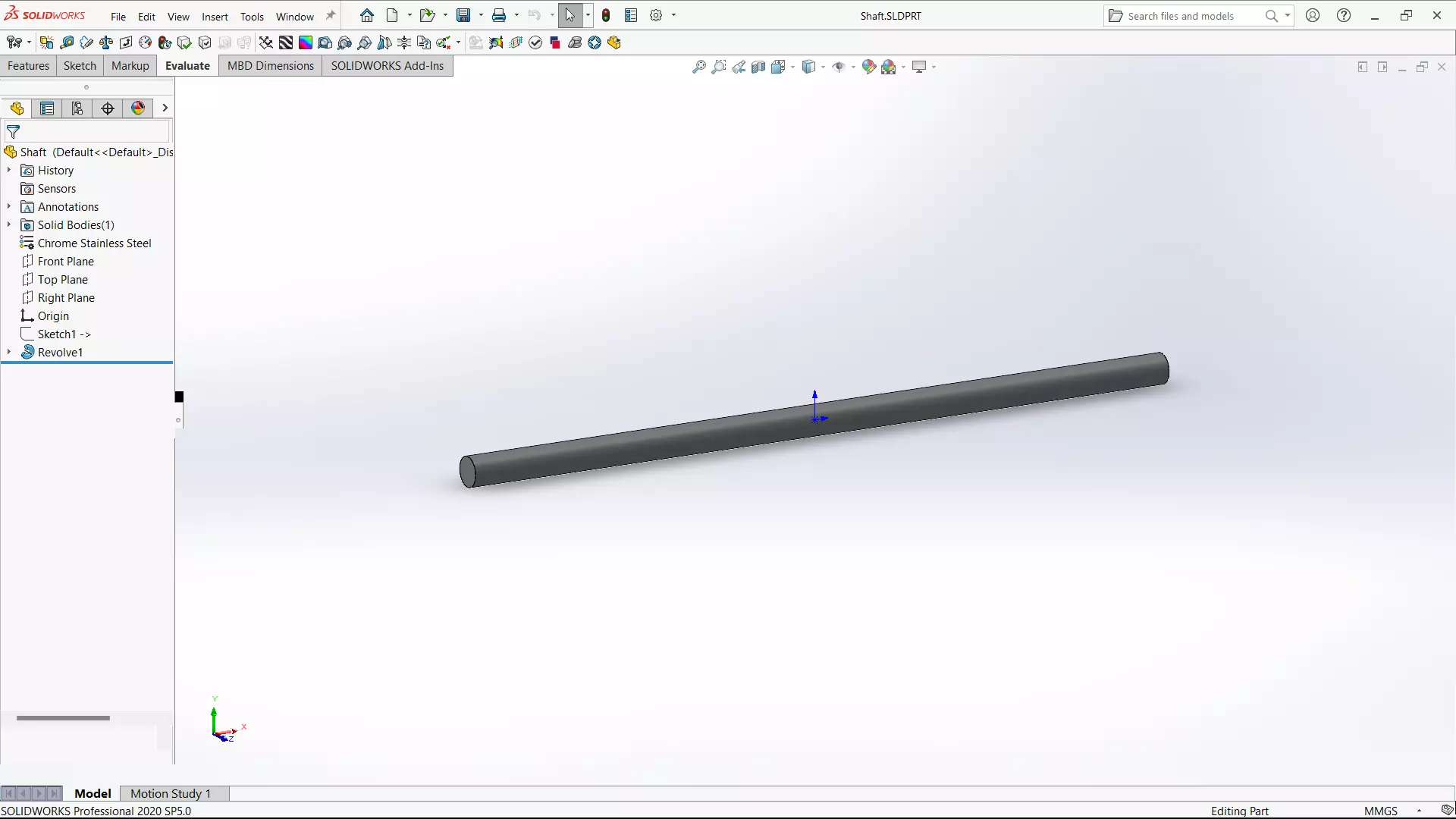

- 2mm OD 50mm length steel shafts for rollers

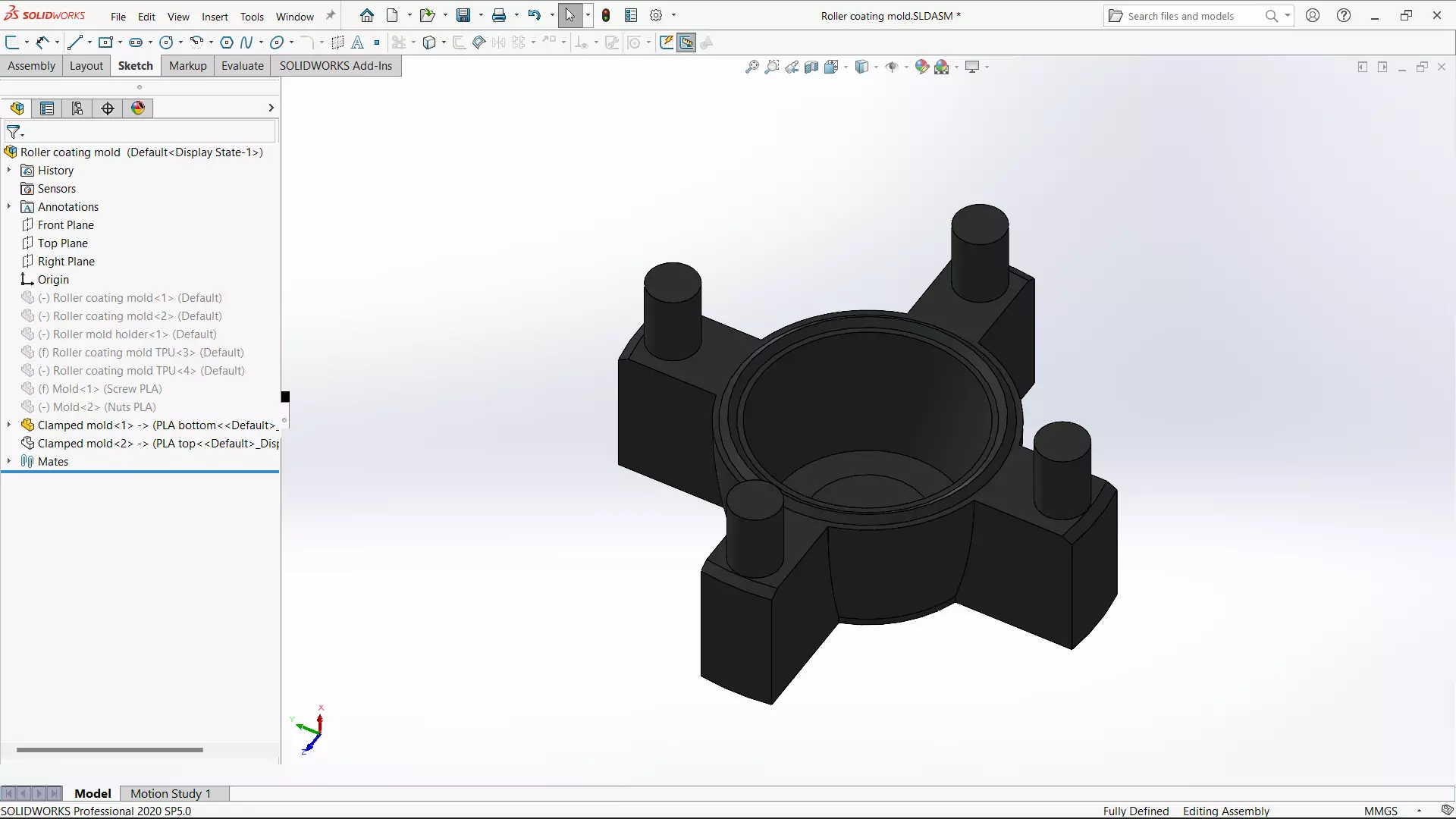

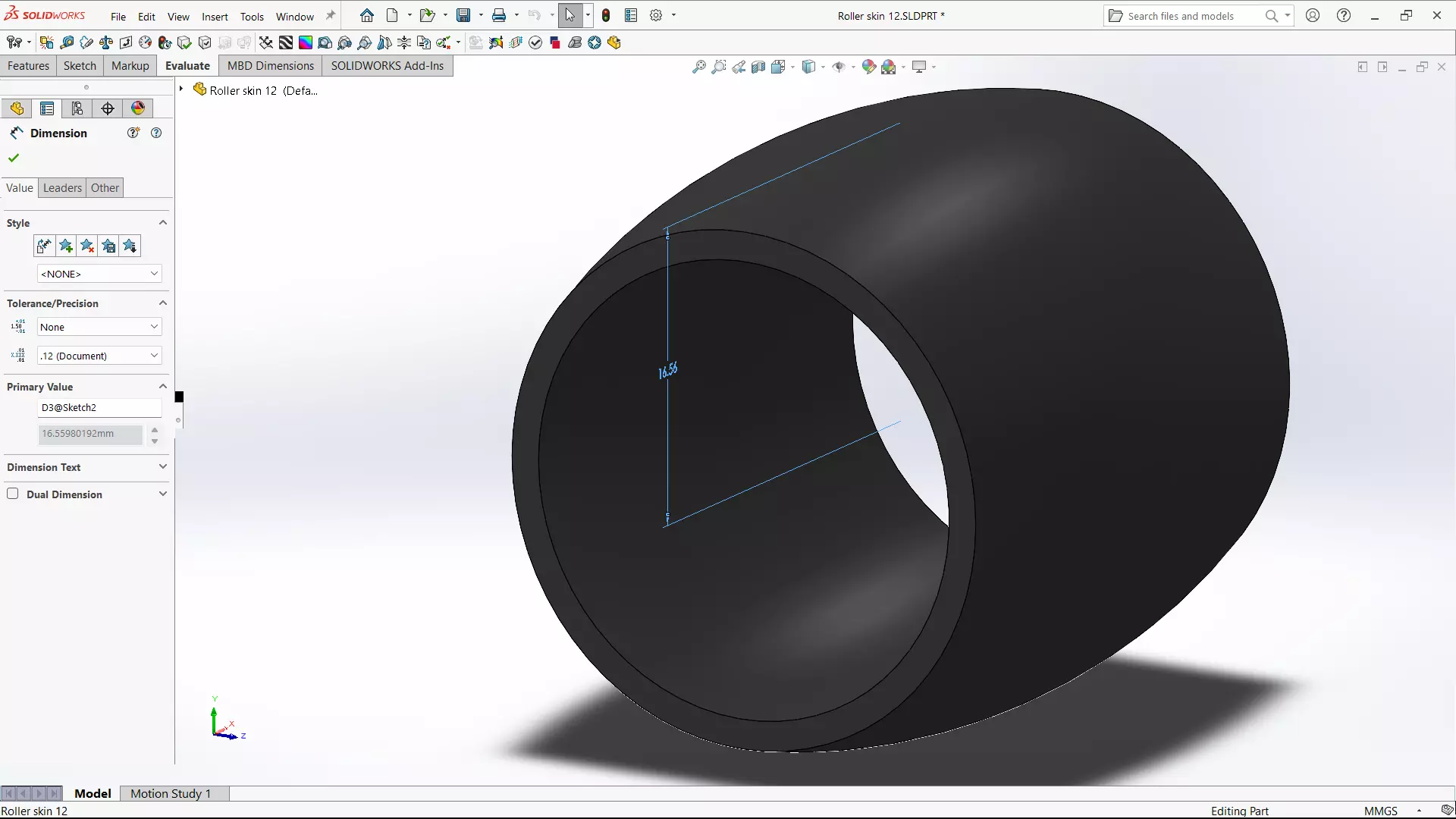

Applying urethane rubber overmolding to omni-wheel rollers has produced - in my opinion - hands-down best performing and professionally looking omni-wheels compared to using soft TPU as roller jackets. That includes my experimens with cutting soft tubing (a samples kit ordered from McMaster-Carr) to use it as roller jackets.

The roller coating process does take extra effort, but it seems worth it. I will write up instructions on DIY urethane rubber overmolding in a separate article.

Soft silicon rubber overmolding seems to work best if the wheel load is relatively light - perhaps one pound of weight per omni-wheel, which may be appropriate for a 3D-printed omni-wheel design. Omni-wheel rollers coated with Shore 60A silicon rubber have floor traction “just right” for my purposes.

|

|

|

|

|

|

|

|

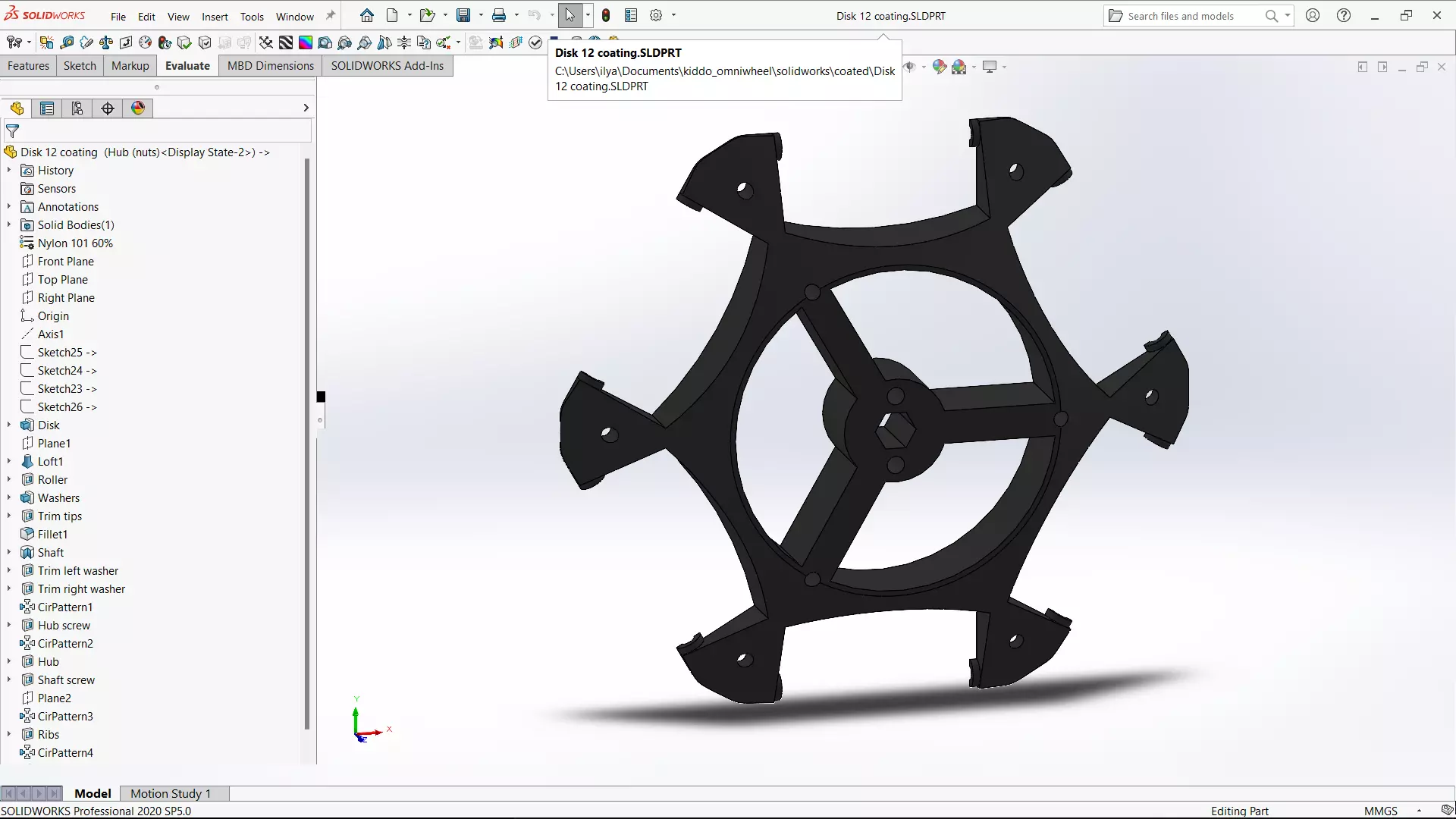

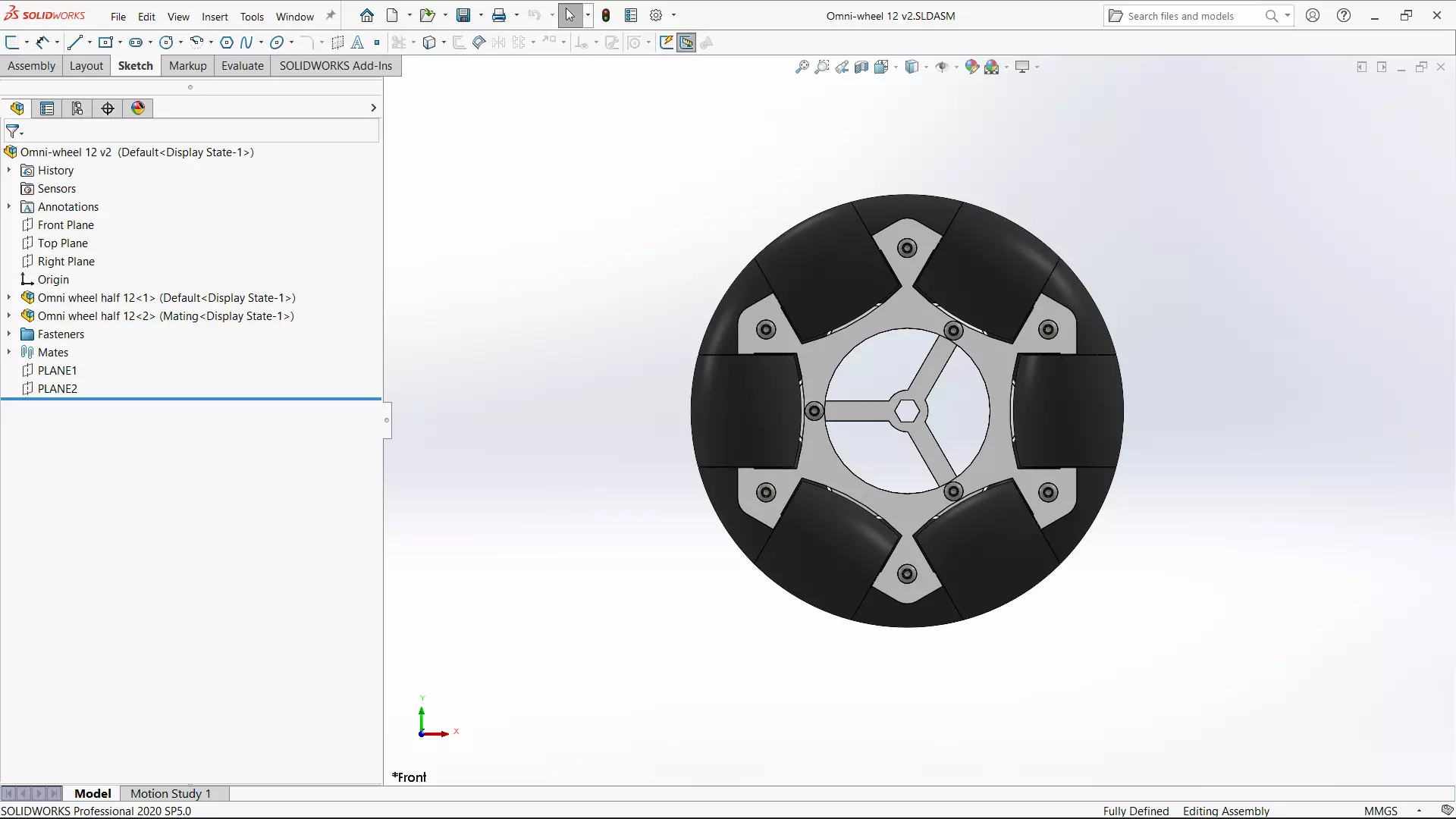

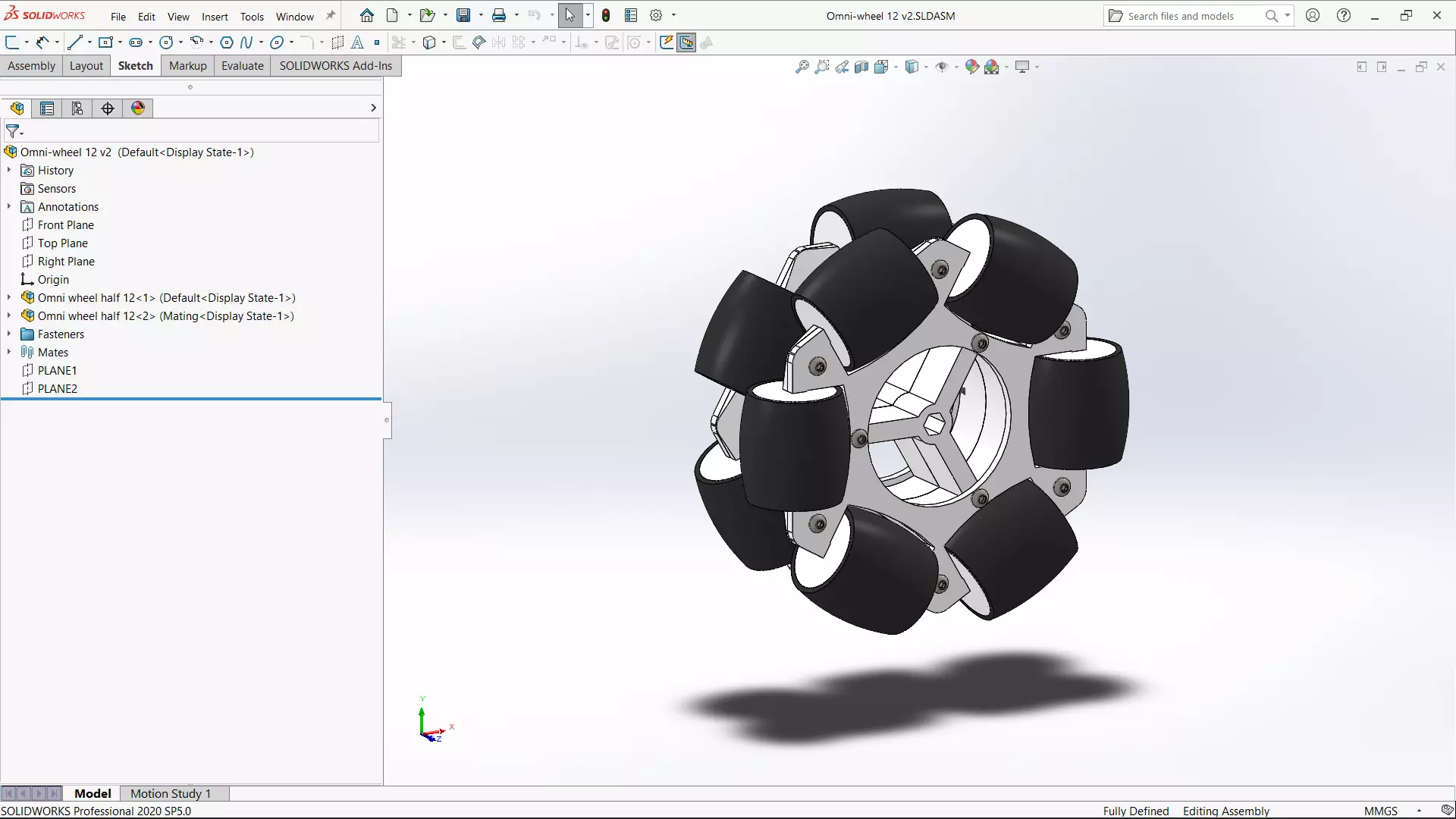

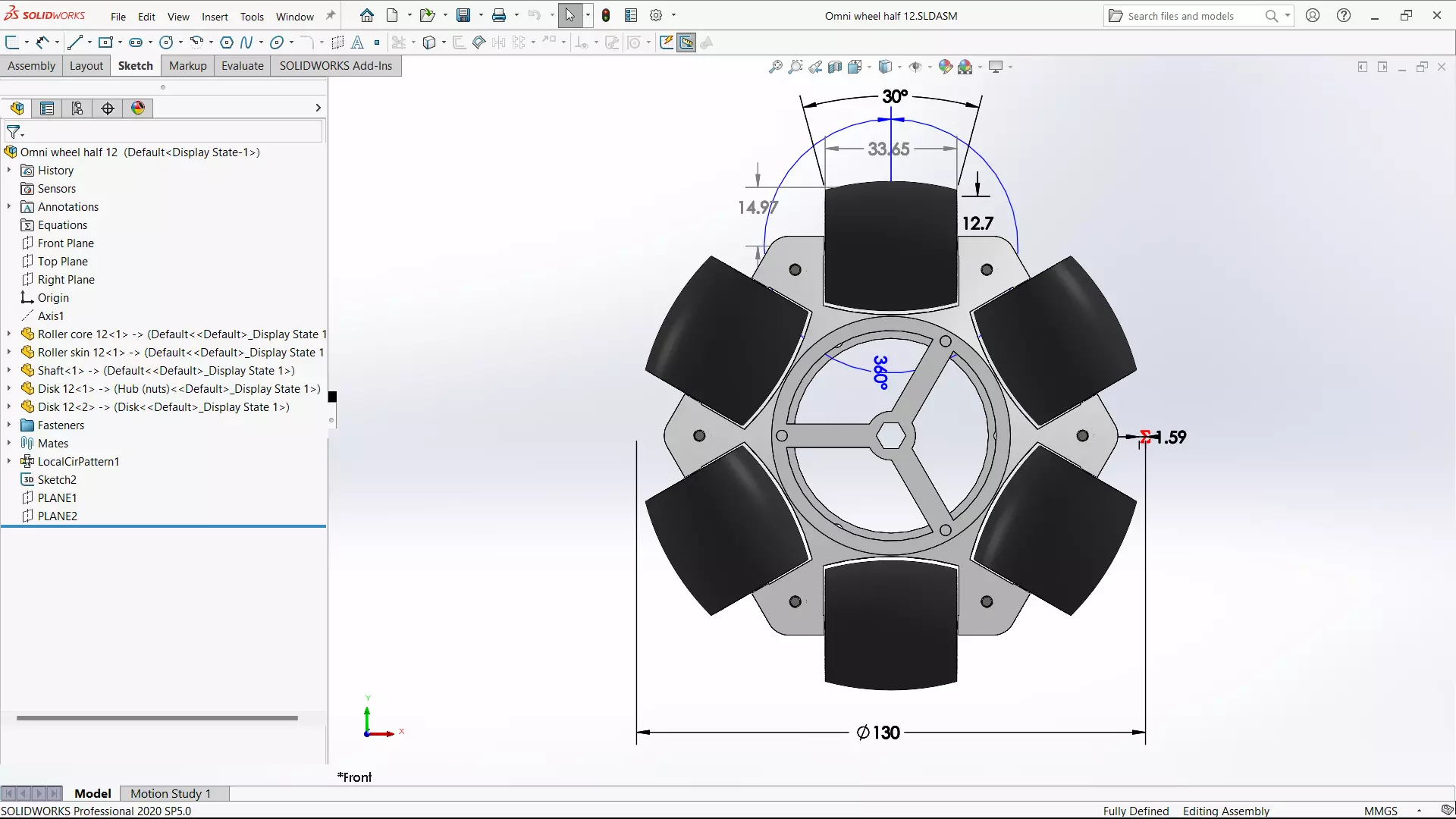

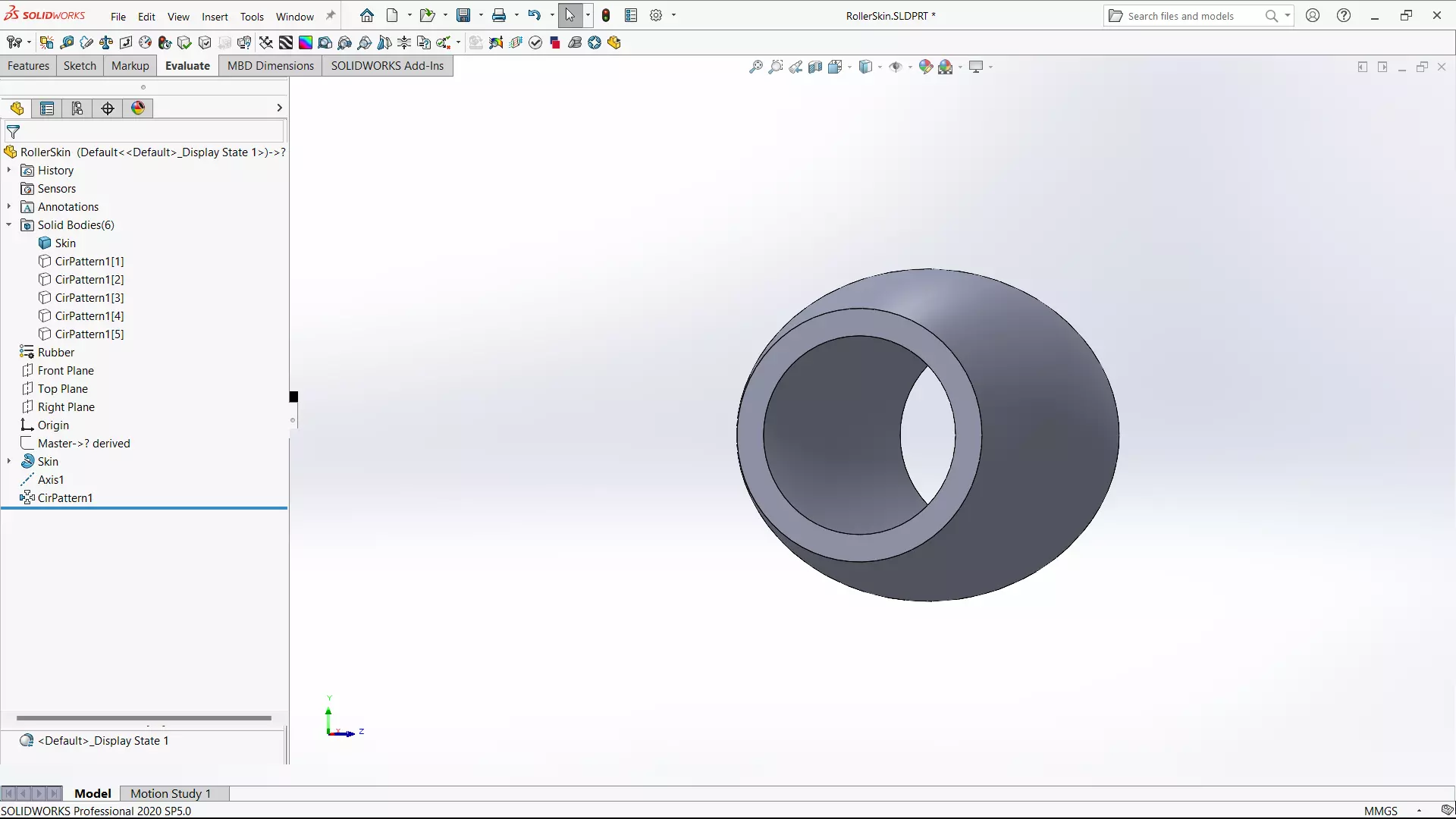

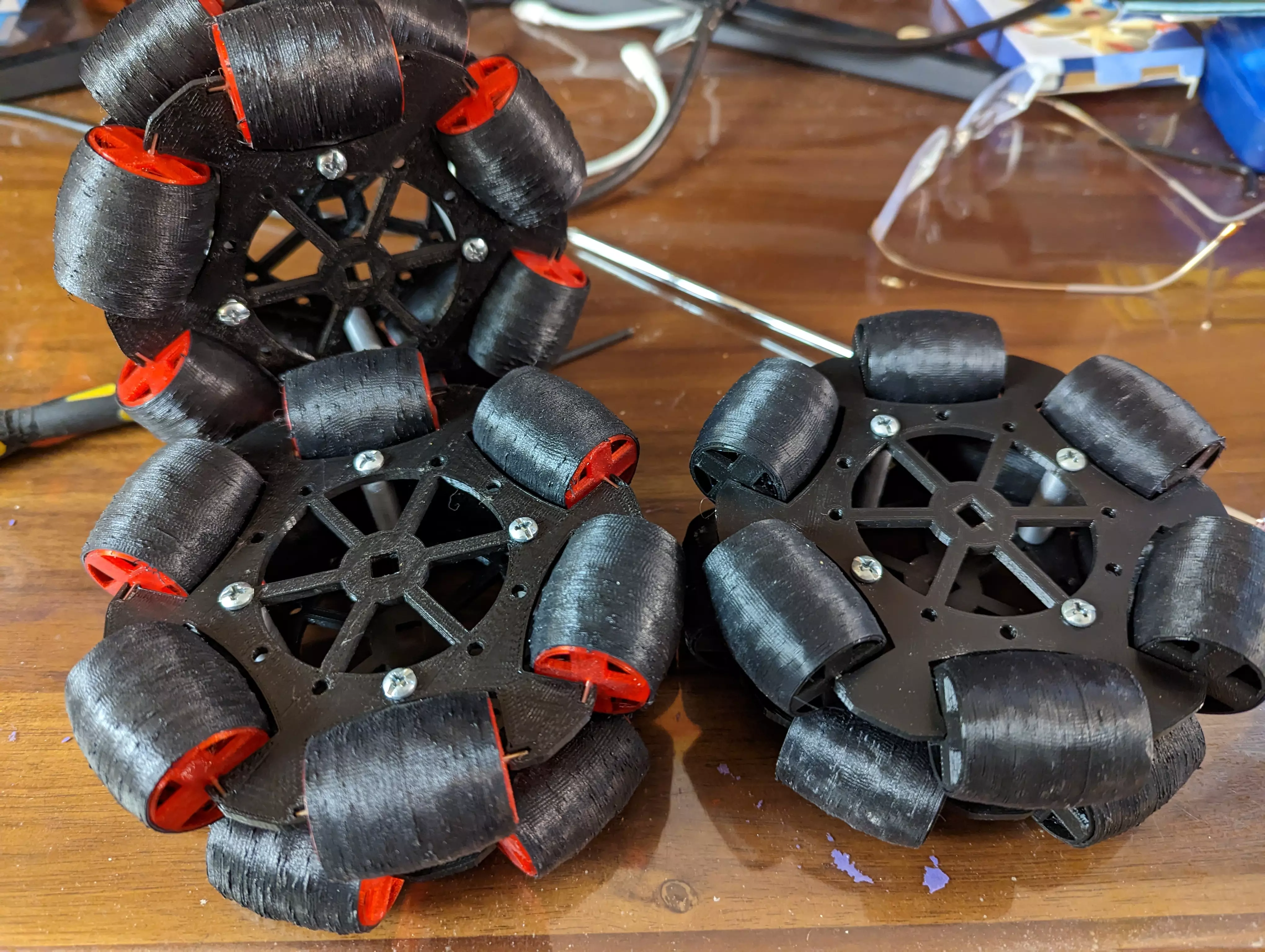

A omni-wheel with soft TPU roller jackets

- 12-rollers

- 130mm OD

- 2mm OD 50mm length steel shafts for rollers

- roller jackets made of 3D-printed soft TPU

If the wheel load is relatively light - perhaps one pound of weight per omni-wheel, which may be appropriate for a 3D-printed omni-wheel design - I don’t recommend making roller jackets from TPU.

This is because TPU filament available for purchase (Shore Hardness 85A or 95A) appears to be too hard for such light loads. The rollers don’t have a good traction with the floor - compared with silicon rubber-coated rollers. That said, I would reconsider using soft TPU for (much) heavier loads.

|

|

|

|

|

|

|

|

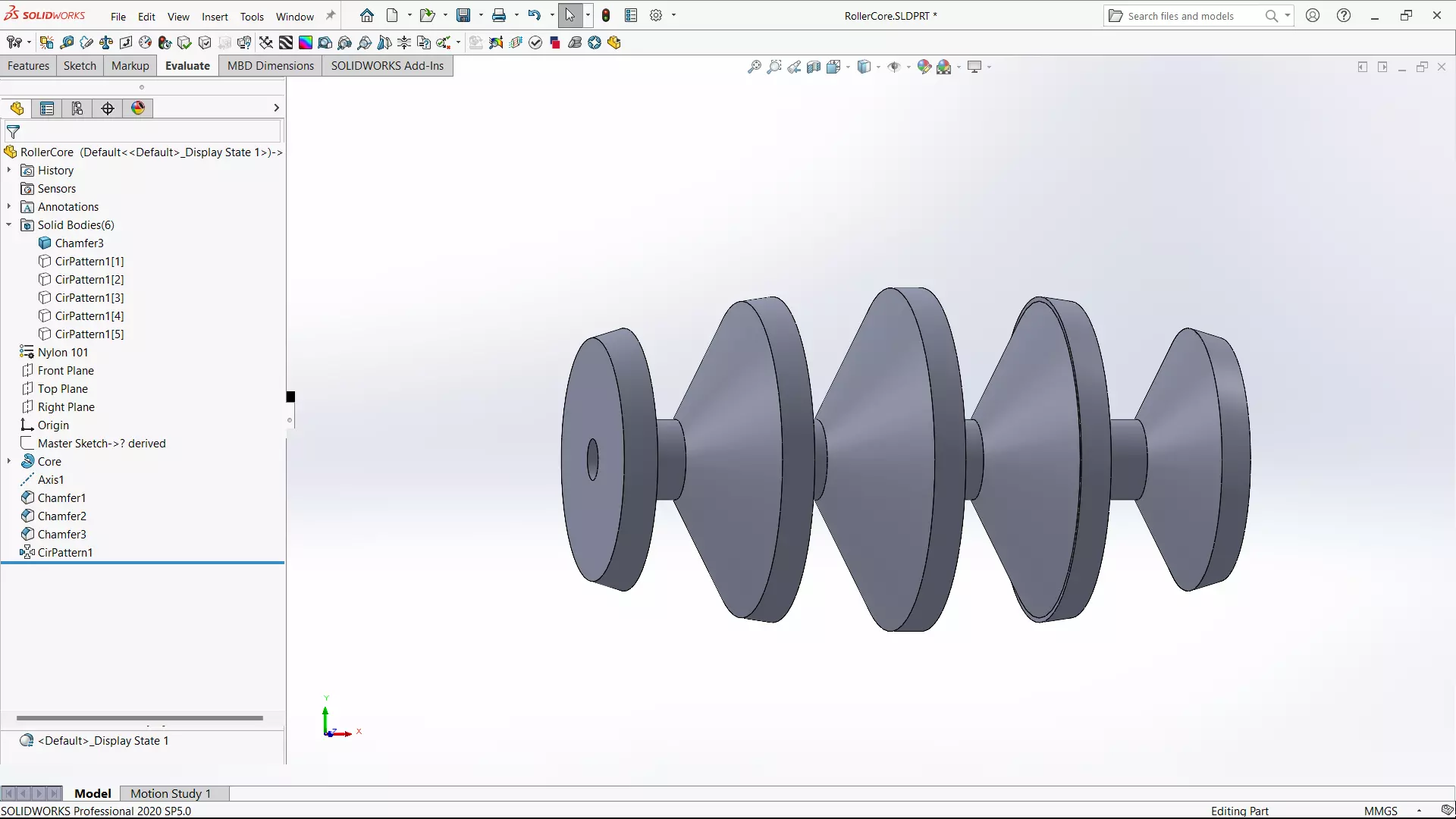

A deprecated wheel with soft TPU roller jackets

- 12-rollers

- roller jackets made of 3D-printed soft TPU

|

|

|

|

|

|

Please find all files in this Maker’s Pet GitHub repository available for download.

Happy 3D printing!